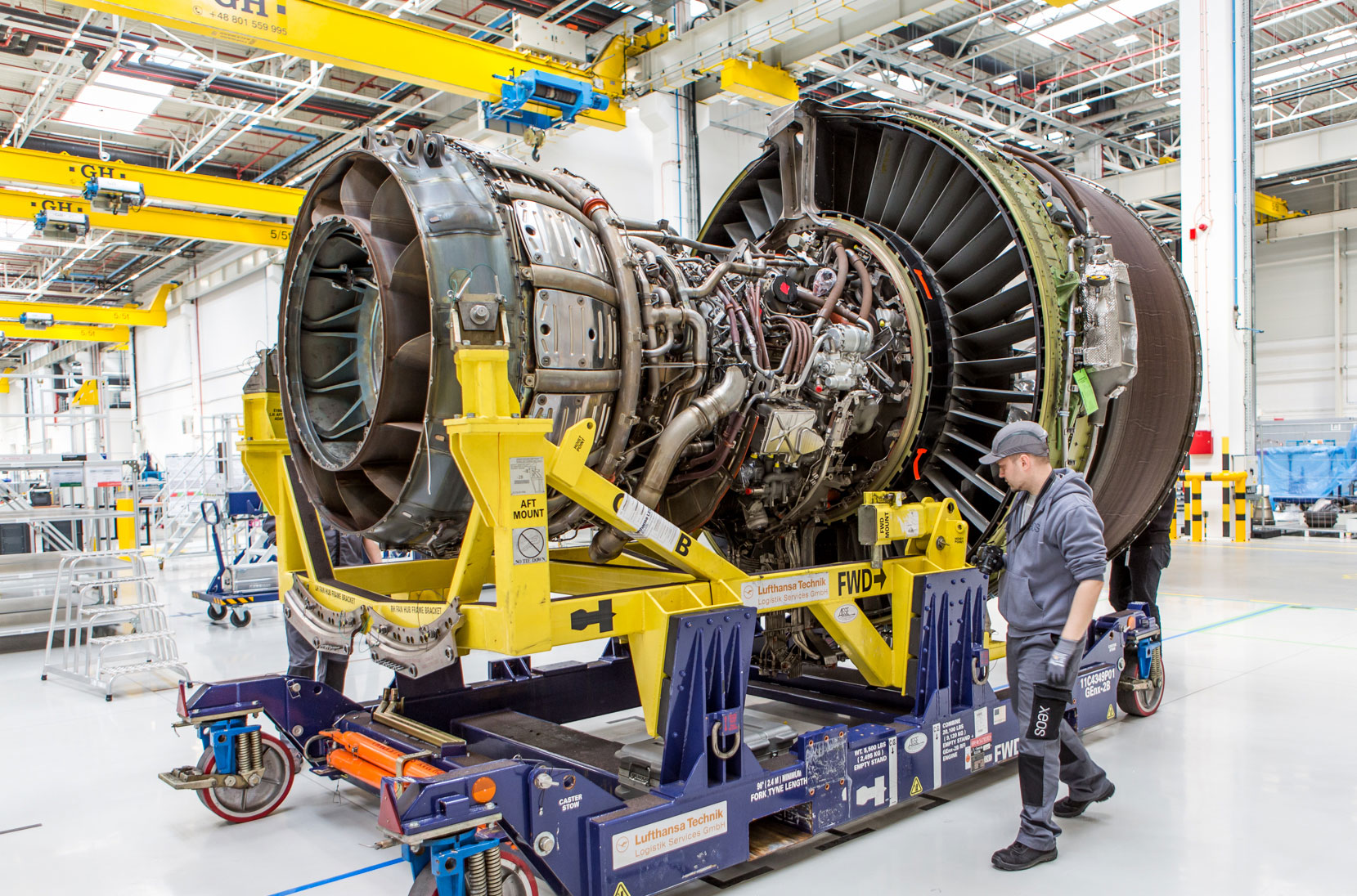

For over 65 years, GH Cranes & Components has been at the forefront of designing and manufacturing overhead cranes, leveraging its deep expertise to meet the specialized requirements of the aeronautics industry. This sector demands precision and efficiency to handle lightweight yet large components, ensuring seamless assembly and handling processes.

Custom Overhead Crane Solutions for Aeronautics

1. Large Beam Spans with High-Precision Hoists

Aeronautical manufacturing involves handling oversized yet lightweight parts. GH Cranes & Components’s overhead cranes feature wide spans and precision hoists to streamline assembly tasks, ensuring exact positioning without delays.

2. Crane Transfer Systems for Enhanced Workflow

Transfer cranes equipped with WiFi connectivity enable the smooth movement of components across different factory zones. This mobility optimizes production workflows and increases operational efficiency.

3. Semi-Automatic and Automatic Cranes

GH Cranes & Components provides PLC-controlled systems, reducing manual inefficiencies and boosting precision with electronic anti-sway systems. These solutions speed up work cycles and improve targeted positioning.

4. Multipoint Hanging Cranes for Stability

With single- or double-girder options, these cranes navigate multiple hanging beams with precision, ensuring stable operation with closed-loop inverter controls and advanced rollers to prevent crossing effects.

Advanced Features for the Aerospace Sector

GH Cranes & Components has partnered with aerospace OEMs and parts manufacturers worldwide, delivering solutions tailored to the unique demands of aeronautics. Whether ensuring smooth component transfer or reducing energy costs with efficient systems, GH Cranes & Components’s innovative overhead cranes enhance productivity while prioritizing safety and reliability.

Partnering with Aerospace Innovators

- Multiple Speed Options: From micro speeds for precise positioning to up to 120 m/min travel speeds for faster workflows.

- Restricted Zone Controls: Protected areas prevent human error and safeguard equipment.

- Synchronization Technology: Closed-loop systems ensure stable lifting with multiple points, enhancing safety and load precision.

- Overload Prevention: Electronic sensors detect and warn about overloads, safeguarding the crane and its components.

- Energy Efficiency: Regenerative inverters save energy, feeding up to 5% back into the grid.

Conclusion

GH Cranes & Components’s expertise in overhead crane manufacturing for the aeronautics industry ensures custom solutions designed for precision, efficiency, and safety. From automated features to energy-saving technologies, GH Cranes & Components continues to support aerospace manufacturers in achieving streamlined, high-performance operations.