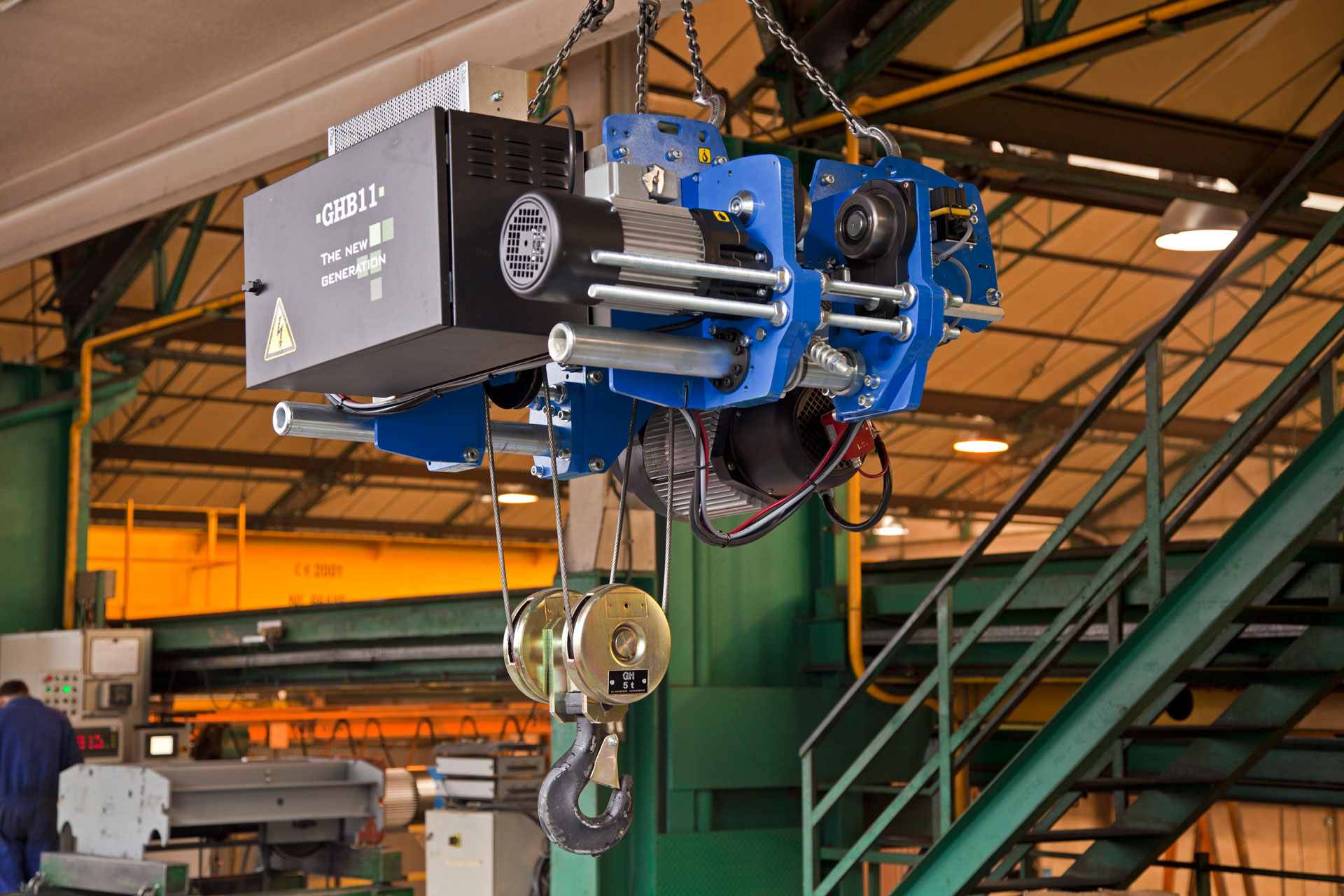

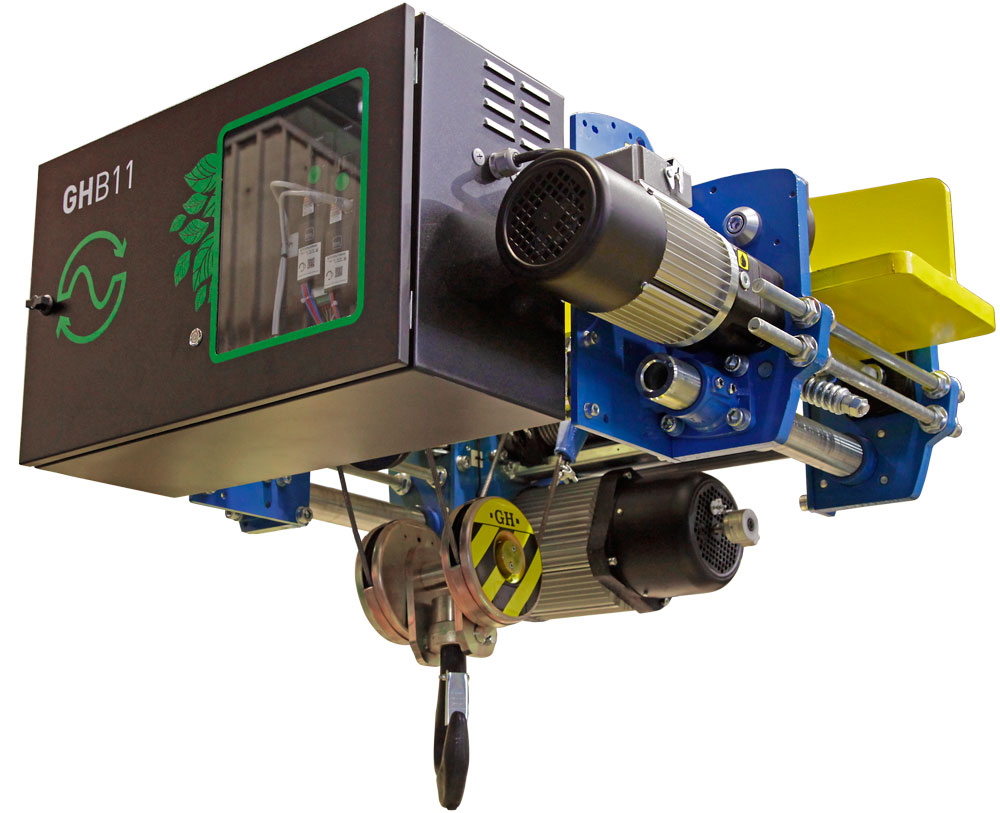

Safety and reliability are critical in the lifting industry, and GH Cranes & Components continues to lead innovation with cutting-edge solutions. One of the latest advancements in overhead cranes is Brake Monitoring, a system designed to enhance safety, extend the lifespan of lifting equipment, and prevent potential failures.

By continuously monitoring the brake system, GH ensures that its overhead cranes operate with maximum efficiency and safety. Below, we explore the advantages of this advanced brake monitoring system and how it contributes to safer and more reliable lifting operations.

Advantages of Brake Monitoring in Overhead Cranes

1. Increased Safety and Durability

The Brake Monitoring system actively detects brake pad wear and ensures that the lifting brake functions correctly, reducing the risk of accidents and extending the lifespan of GH hoists.

- Prevents motor issues caused by lifting when the brake is not fully released.

- Avoids potential load drops due to brake contactor malfunctions.

- Detects brake pad wear in real time, preventing hazardous situations.

2. Real-Time Brake Monitoring for Maximum Security

A high-precision sensor continuously monitors the status of the brake, ensuring proper synchronization between the brake and lifting motor.

- If the brake does not release when starting a lift, the motor is deactivated, preventing operation under unsafe conditions.

- At the end of the lifting operation, the system guarantees that the brake is fully applied before the motor is de-energized.

3. Direct and Accurate Wear Monitoring

The thickness of the brake pad is continuously checked to prevent excessive wear and ensure optimal performance.

- If the wear threshold is reached, the system stops the overhead crane to prevent further damage.

- An optional brake wear warning signal alerts operators before critical wear levels are reached.

4. Simple and Reliable Technology

GH’s Brake Monitoring system offers a straightforward yet highly effective solution that requires no manual adjustments and is easy to retrofit on existing hoists.

- Uses a single sensor for both brake status and wear detection.

- Direct measurement eliminates interpretation errors.

- Not affected by temperature or magnetic fields, ensuring consistent performance.

Conclusion

With the integration of Brake Monitoring technology, GH Cranes & Components reinforces its commitment to safety, reliability, and innovation in the overhead crane industry. By continuously monitoring brake performance and wear, this system enhances operational safety, reduces maintenance costs, and prolongs the lifespan of lifting equipment.

For industries that prioritize efficiency and safety in their lifting operations, GH overhead cranes with Brake Monitoring technology offer the perfect combination of performance and reliability.

Discover how GH Cranes & Components can optimize your lifting operations with the latest advancements in crane safety and technology!