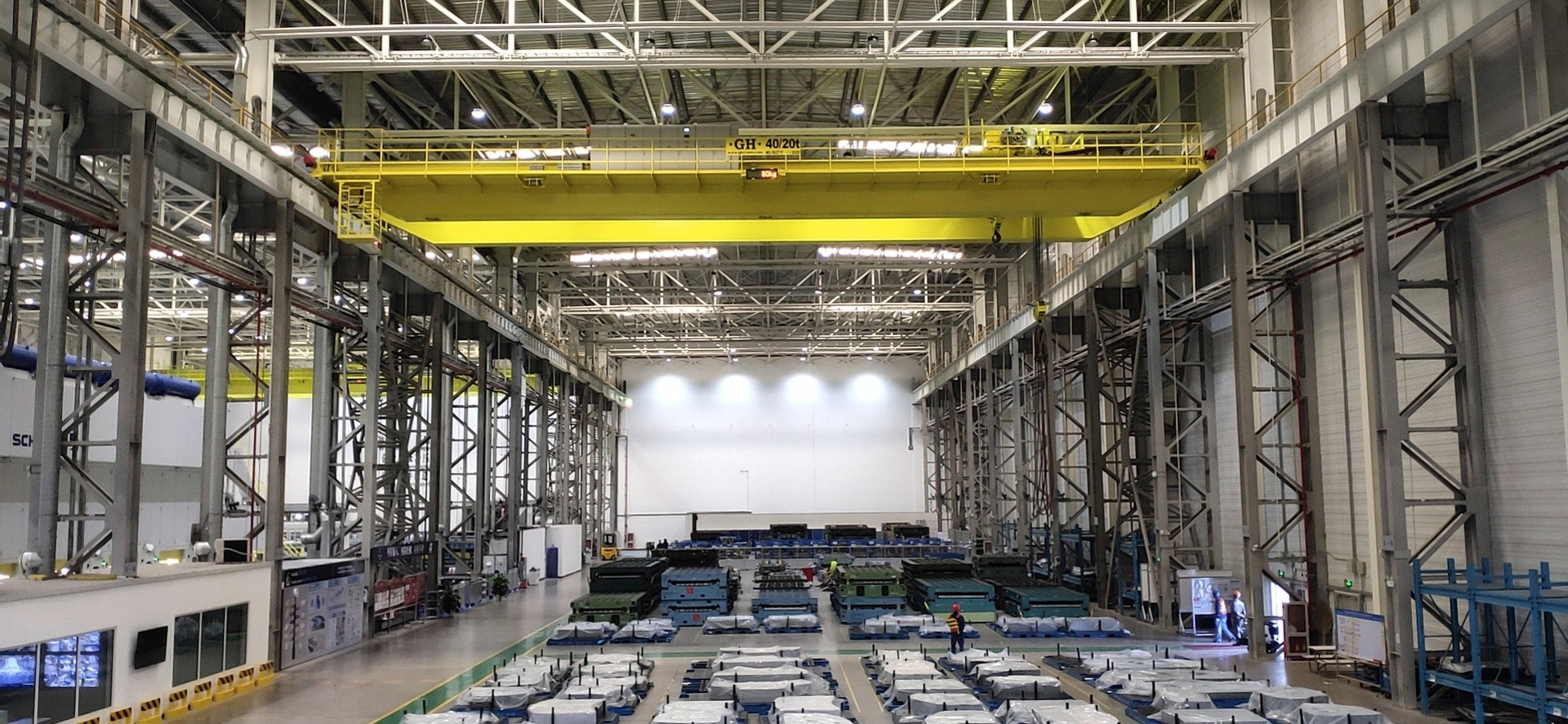

In the fast-paced and highly automated world of automotive manufacturing, precision, safety, and efficiency are non-negotiable. At GH Cranes & Components, we provide advanced overhead crane solutions specifically designed for the unique needs of the automotive sector — from coil storage and stamping to assembly and die handling.

With installations across automotive plants on five continents, our overhead cranes have become an integral part of press lines, component warehouses, and assembly operations. Whether the need is for custom lifting systems or high-capacity standard hoists, GH offers reliable and tailored crane solutions that move with the speed of the industry.

Advantages of GH Overhead Cranes in the Automotive Sector

1. Coil Storage and Handling

Managing heavy coils requires precision and repeatability. GH overhead cranes are equipped with coil-specific handling tools and options for semi-automatic and fully automatic operation. Each crane is custom-configured to work with your existing warehouse tools, ensuring smooth integration and safe material movement.

- Customizable configurations for coil warehouse management

- Automation-ready for enhanced safety and efficiency

- Robust performance with cycle assurance features

2. Stamping Die Handling and Tilting

Stamping dies require careful handling, especially during tilting and positioning operations. Our double-hook overhead cranes feature multiple lifting heights on the same bridge, offering the stability and control needed to ensure safe die movements.

- Double-hook hoists for synchronized tilting

- High-speed and micro-speed options for delicate maneuvers

- Widely used in stamping operations across global automotive facilities

3. Automotive Parts Manufacturing

Automotive parts production involves varied lifting needs — from delicate components to heavy machinery. GH offers both standard and custom-built overhead cranes, including transfer cranes with micro-speed control and underslung systems for space-restricted areas.

- Versatile hoist options for multiple manufacturing setups

- Improved operational flexibility and safety

- Seamless integration into existing workflows

4. Automotive Assembly Line Support

At the final stage of the production line, our overhead cranes handle the most critical and heavy-duty lifting tasks. GH wire-rope hoist cranes (up to 20 tons) and chain-hoist cranes work around the clock in assembly plants around the world, supporting continuous and safe production flow.

- Reliable lifting equipment for 24/7 operations

- Installed in major automotive brands’ assembly plants

- Designed for both heavy-duty and precision lifting

Conclusion

At GH Cranes & Components, we understand that the automotive industry demands precision, uptime, and adaptability. That’s why our overhead cranes are engineered to handle the full range of automotive processes — from coil handling and die tilting to component manufacturing and final assembly.

With decades of expertise and a global footprint, GH delivers overhead crane solutions that keep your production lines moving, your operations safe, and your performance ahead of the curve.

Looking to elevate your automotive manufacturing capabilities? Trust GH Cranes to do the heavy lifting.