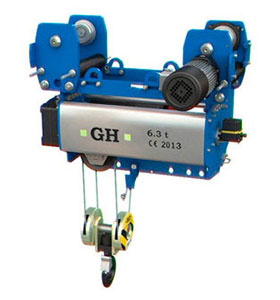

The new range of GH Hoists have been designed with the following principles; reliability, security, durability, price and easy maintenance. The design is rectangular, modern, compact with perfect dimensional balance.

Cutting-edge design technology, highly sophisticated production resources and efficient organization have placed GH among Europe´s top lifting equipment manufacturers.

The functional arrangement of the different elements are standardised on a modular construction, permitting the easy interchangability of groups combining different lifting speeds, heights and duty factors, according to the requirements and working conditions of each application.

GH hoists are fitted with a standard control system and monitoring of Safe Operation Period. The possibility to check in any moment the actual use of your machine will help the preventive maintenance.

The construction of the GH electric wire rope hoist, is based on the rules and regulations of lifting devices according to the FEDERATION EUROPEENNE DE LA MANUTENTION (FEM) and the standards I.E.C.

Low headroom single girder electric hoists (GHB11)

The low headroom configuratión is the standard for the best use of under-beam space in single girder cranes.

Wheels can be flat or angled to suit different type of bottom flanges and running profiles, to improve behavior and increase duration.

Normal headroom single girder electric hoists

The normal headroom single girder configuration, is the traditional solution in single girder cranes when space under beam is not important. This configuration is suitable for 1/1 and 2/2 reevings hoists.

Another relevant use is in cranes with load transfer between halls.

Wheels can be flat or angled to suit different type of bottom flanges and running profiles, to improve behavior and increase duration.

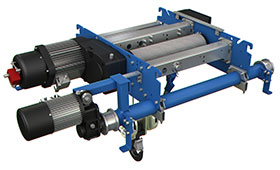

Double girder electric hoists on end carriage

Pre-designed solutions for trolleys with 2 hoists, rotating trolleys, etc…

Available options like manual brake release, weighing system, additional safety brake, etc…

Compact double girder electric hoists

The highest quality at best price in double girder cranes.

This GH hoist is the most compact double girder hoist available in the market.

A simple and robust design gives it a competitive advantage.

Normal headroom single girder electric hoists ready for curves

The perfect solution when moving loads along paths with turns and changes of direction.

Wheels can be flat or angled to suit different type of bottom flanges and running profiles, to improve behavior and increase duration.

Chain hoists

From 100 kg to 5000 kg of capacity, in versions: fixed, single girder, manual trolley, motorised trolley.

Rugged and compact, of modular construction and easy maintenance.

High capacity hoist

The functional arrangement of the different elements are standardised on a modular construction, permitting the easy interchangability of groups combining different lifting speeds, heights and duty factors, according to the requirements and working conditions of each application.

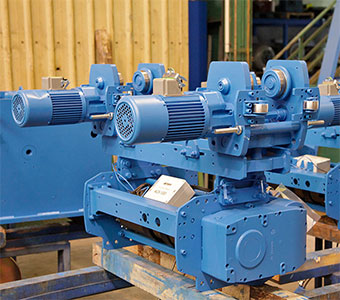

Open winch

For process cranes and high capacities.

These type of crabs are produced on demand to address special needs such process cranes with special features of capacity, safety, speed or other requirements.

It is called Open Winch due to all the elements are manufactured with independent and different sub-assemblies for easy maintenance.

GH sells in more than 70 countries through our experienced sales team and local distributors.

More than 125,000 bridge cranes installed vouch for our experience.

GH started out in 1958, as a manufacturer of lifting components. Manufacture of hoists, cranes and crane components, although in its manufacturing range can find, gantry cranes, cantilever cranes, jib cranes, transfer carts, boat hoists, rubber type gantries.

We now operate in over 70 countries, installing our products and providing solutions for practically all sectors.

Our years of experience and our customers' recognition of the high quality of our products have placed GH among the leading European manufacturers in the lifting sector.

GH Cranes & Components USA

ghcranesusa@ghcranes.com

Spare Parts & Components

9134 Gulfstream Road Frankfort, IL 60423

T: 815.277.5328

Manufacturing & Service

14891 Hwy 205 Terrell, TX 75160

T: 972.563.8333